In the realm of industrial manufacturing, precision and reliability are paramount. The choice of materials plays a vital role in ensuring the durability and performance of the products produced. One such material that has stood the test of time is brass. Brass fittings, in particular, have been widely used in various industries due to their exceptional qualities. To fully harness the benefits of brass fittings, machining is an essential process that adds significant value to your industrial business. Let's delve into the reasons why machining brass fittings is crucial for your operations.

Customization and Versatility:

Machining brass fittings provides the flexibility to create custom designs tailored to your specific requirements. With the help of advanced machining techniques, you can easily shape, cut, and form brass fittings into intricate and precise configurations. This level of customization allows your industrial business to adapt to unique challenges, meet specialized needs, and produce fittings that seamlessly integrate with your existing systems.

Superior Strength and Durability:

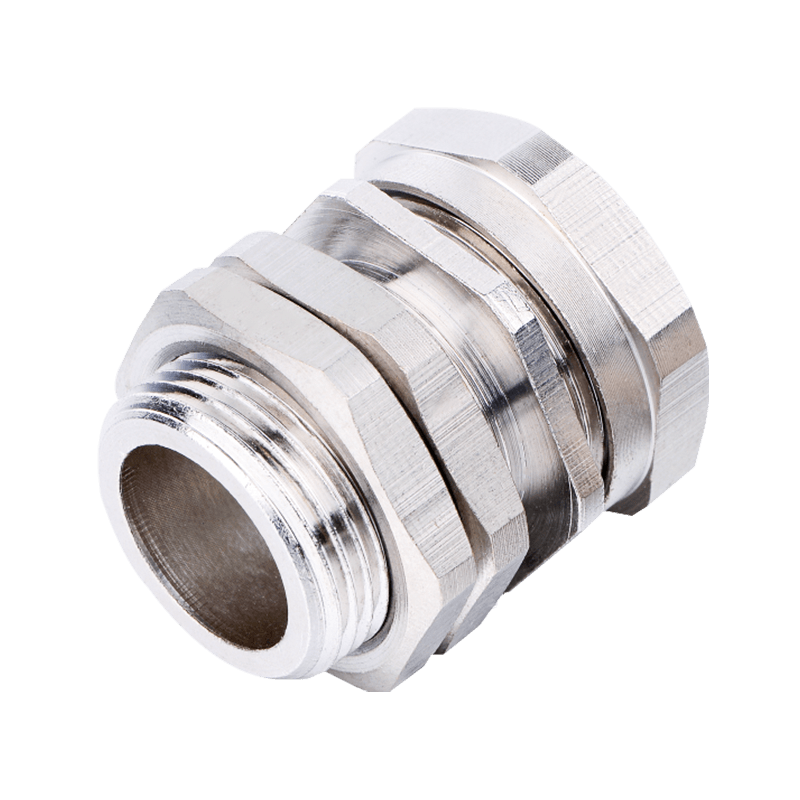

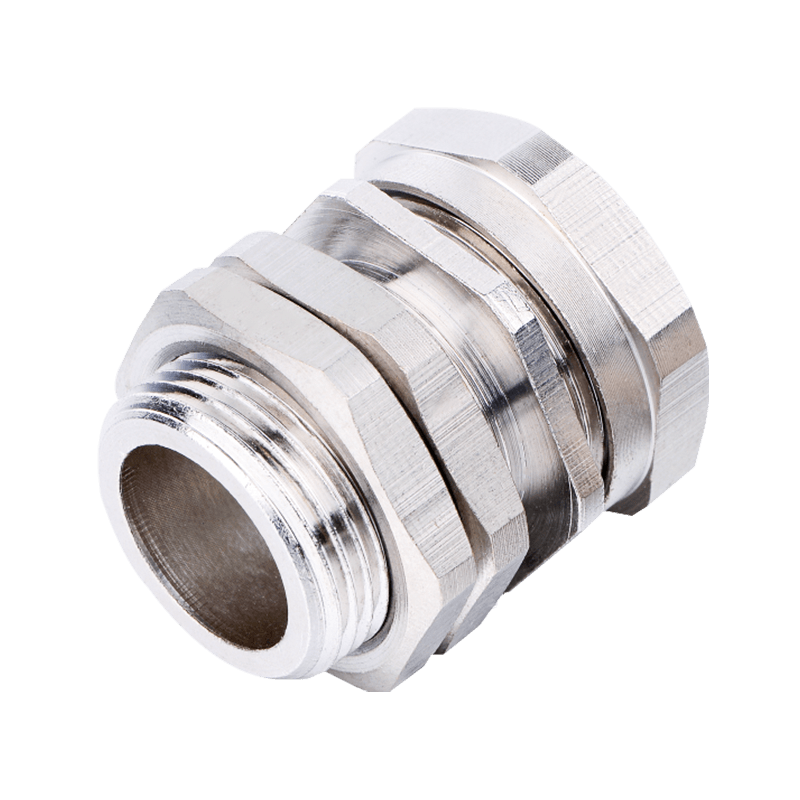

Brass fittings are renowned for their exceptional strength and durability. The machining process further enhances these qualities by removing imperfections, optimizing the surface finish, and ensuring precise dimensions. Machined brass fittings exhibit excellent resistance to corrosion, wear, and high temperatures, making them ideal for demanding industrial applications. Their durability translates into extended product lifecycles, reducing maintenance costs and enhancing overall operational efficiency.

Enhanced Performance:

In many industrial processes, performance is a critical factor.

Machining brass fittings allows for the creation of components with precise tolerances, ensuring reliable and consistent performance. By achieving tight tolerances and fine surface finishes, machining maximizes the efficiency and functionality of brass fittings. Whether it's fluid flow control, sealing, or connecting components, machined brass fittings provide the level of performance needed to optimize your industrial processes.

Cost-effectiveness:

While brass fittings may have a higher upfront cost compared to some alternative materials, their long-term cost-effectiveness is undeniable. Machining brass fittings ensures that each component is precisely manufactured, reducing the risk of failures, leaks, or malfunctions. The enhanced durability and performance of machined brass fittings translate into minimized downtime, improved productivity, and reduced maintenance and replacement costs. Investing in quality brass fittings that undergo machining can lead to significant long-term savings for your industrial business.

Compatibility and Safety:

Brass fittings offer excellent compatibility with various materials commonly found in industrial applications, such as water, gases, chemicals, and fuels. Machining further ensures the dimensional accuracy and tight tolerances required for proper fitting connections. This compatibility reduces the risk of leaks and enhances safety in your industrial operations. Additionally, brass is a non-sparking material, making it suitable for environments where flammability and explosion hazards are a concern.

In conclusion, machining brass fittings is an essential process that adds value to your industrial business. The ability to customize fittings, enhance their strength and durability, improve performance, achieve cost-effectiveness, and ensure compatibility and safety are all critical advantages of machining brass fittings. By incorporating machined brass fittings into your industrial processes, you can enhance productivity, reliability, and efficiency while maintaining high-quality standards.

CNC milling is a precise method of machining that uses computer-controlled cutting tools to remove material from the brass fitting. This process can produce precise and accurate fittings with tight tolerances and specific shapes and sizes.Machining brass fittings with nickel plating can be done using various methods, such as CNC milling, turning, drilling, and grinding. The choice of method will depend on the specific design and size of the fitting, as well as the desired level of precision and surface finish.Turning is a method of machining that uses a lathe to rotate the brass fitting and a cutting tool to remove material. This process can be used to create round or cylindrical fittings with a smooth surface finish.